silverworks tools list

Tools at SilverWorks Studio & Gallery are provided for every class, workshop, and open studio time. Just come and play!

What do we have?

SilverWorks is my personal working studio that I invite my students and others to use. Because of the way I work, the studio does not have a traditional “jewelers studio” feel. You won’t find a jeweler’s bench in my space... I hate them. But you might find a new sense of inspiration!

Acetylene Torch, four stations:

The torch we use to heat the silver for annealing, soldering, and fusing.

Anvil (steel block):

A surface used to hammer against.

Bench Shear:

A heavy duty tool that smoothly cuts through sheet metal up to 10 gauge.

Copper Tongs:

For removing silver from the pickle.

Dapping Block:

A wooden block used to create convex or concave shapes. Steel block for creating beads and semi-spheres.

Disc Cutter:

Creates perfect circles up to 1 1/4” in diameter.

Shape Cutters:

Punches ovals, rectangles and hearts.

Letter Stamps:

Alphabet stamping tools for imprinting letters into non-ferous metals.

Pliers:

Round-nose, Flat-nose, Chain-nose

Pliers are for bending and shaping wire. The shape of the desired bend dictates the choice of the plier.

Side Cutters:

For cutting wire. Maximum cut 20 gauge.

Shears:

For cutting sheet metal.

Hammers:

Ball-Peen, Chasing, Forging, Rivoting. Used for shaping, forging and creating surface textures.

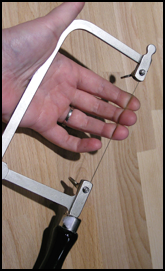

Jeweler’s Hand Saw:

For cutting fine designs in sheet, wire, and tubing. We use a #3 blade.

Flexible Shaft:

A hand drill operated with a foot pedal. Used for drilling, cutting, and polishing of fine components.

Polishing Machine:

A motor with spindels that hold buffing wheels. Used in the final polishing process.

Mandrels:

Steel anvils shaped to assist the forging of a particular project. We have a ring mandrel, bracelet mandrel, bangle mandrel, neck mandrel and bezel mandrels.

Pickle Pot:

A crock pot that holds the acid solution called “pickle” that keeps the silver clean during soldering.

Rolling Mill:

Two steel rollers gauged to compress metal to the size needed. Also great for applying texture to metal.

Third Hand:

Tweezers that rest on a base for propping up complex projects.

Tumbler:

A steel drum filled with steel shot and a burnishing compound. Another tool for polishing.

Resources for Classes